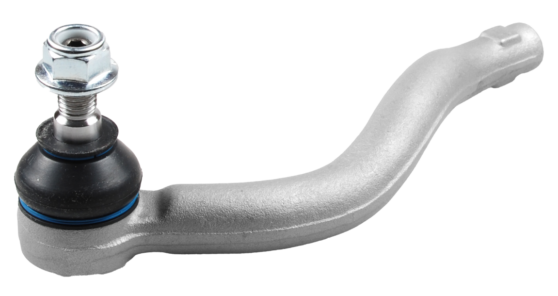

Tie-rod Ends

Quaro tie-rod ends are very strong and durable, which is critical for steering system safety and performance.

Quaro tie rods are tasked with precisely transferring steering wheel movement to the wheels, so their quality is paramount. The surface at the interface of the tie-rod and the steering gear is zinc coated to prevent thread rusting.

-

Effective Protection

The boot protects the inside of the end from dirt, such as dust, sand, or mud, which could compromise steering system performance.

-

Reduced Wear

The flexible boot absorbs some of the forces and vibrations that may occur during normal use, reducing the wear on the materials inside the end and extending its service life.

-

Damage Prevention

Thanks to the flexible boot, the end can freely move within its permitted range, which reduces the risk of mechanical damage when turning or on rough surfaces.

Check the list of authorized distributors

Tie-rod ends are critical for the steering system, its stability and handling. Their durability and strength are highly relevant to driving safety and the long-term effectiveness of the steering system.

Patryk Mikiciuk

Quaro Expert

Steering Confidence with Quaro Tie-rod Ends

High quality is very important for the safety and effectiveness of the steering system. The surface of the tie-rod is zinc-coated at the interface with the steering gear to prevent thread rusting. Additionally, the reinforced ball joint guarantees reliability even at high loads.

FAQ

Tie-rod end replacement requires aligning the wheels afterwards.

It is not necessary because the end is a separate component. Before installing the rod end, check the play on the tie-rod. Remember to align the wheels after replacing the tie-rod end.

The tie-rod end links the steering system to the wheel. One end of the tie-rod end is fixed to the knuckle, and the other to the tie-rod. Its failure causes mishandling.

Poor road surface is critical for tie-rod ends.